The realm of space exploration is entering an unprecedented era, driven by ambitious goals of lunar bases, Mars colonization, and deep-space missions. Achieving these aspirations hinges on revolutionary advancements in how we build spacecraft. The future of spacecraft design and manufacturing is characterized by a relentless pursuit of efficiency, autonomy, reusability, and modularity, pushing the boundaries of engineering and materials science. Companies like SpaceX, along with national agencies in the US and UK space sectors, are at the forefront of this technological revolution, shaping the next generation of spacecraft.

Building Spacecraft for the Future: Key Technologies and Methodologies

The construction of future spaceship involves a convergence of advanced materials, innovative manufacturing processes, and intelligent systems:

1. Advanced Materials and Manufacturing

a. Lightweight Composites and Alloys

Future spacecraft will increasingly rely on advanced composites (like carbon-fiber-reinforced polymers) and specialized alloys (such as titanium and nickel-based superalloys). These materials offer exceptional strength-to-weight ratios, crucial for reducing launch mass and increasing payload capacity. They also provide enhanced resistance to extreme temperatures, radiation, and the harsh vacuum of space.

b. Additive Manufacturing (3D Printing)

This technology is a game-changer for spacecraft construction. 3D printing allows for the creation of complex, intricately designed parts with optimized geometries that are impossible or too expensive to produce with traditional methods. SpaceX, for instance, extensively uses 3D printing for components of its Raptor engines and Dragon spaceship, allowing for rapid prototyping, reduced lead times, and lower costs. It also enables the creation of parts with integrated functionalities, minimizing the number of individual components.

c. In-situ Resource Utilization (ISRU) Materials:

For long-duration missions to the Moon or Mars, the ability to “live off the land” will be vital. Future spacecraft are being designed to use materials extracted directly from celestial bodies – for example, using lunar regolith (moon dust) for 3D printing structures or extracting water ice for propellant or life support. This reduces the need to launch all materials from Earth, significantly cutting costs and mission complexity.

2. Modular and Adaptable Designs

a. Modular Spacecraft Buses

The trend is moving towards modular common spacecraft buses (MCSBs) that can be easily adapted for various missions (e.g., orbiters, landers, deep-space probes) by simply swapping out different payload modules. This “plug-and-play” approach drastically reduces design and development time and costs, making spaceship more versatile and cost-effective.

b. Standardized Interfaces

Developing standardized interfaces for docking, power, and data transfer allows different spacecraft components or even modules from different manufacturers to seamlessly integrate, fostering collaboration and flexibility in space operations. This is crucial for building larger structures in orbit.

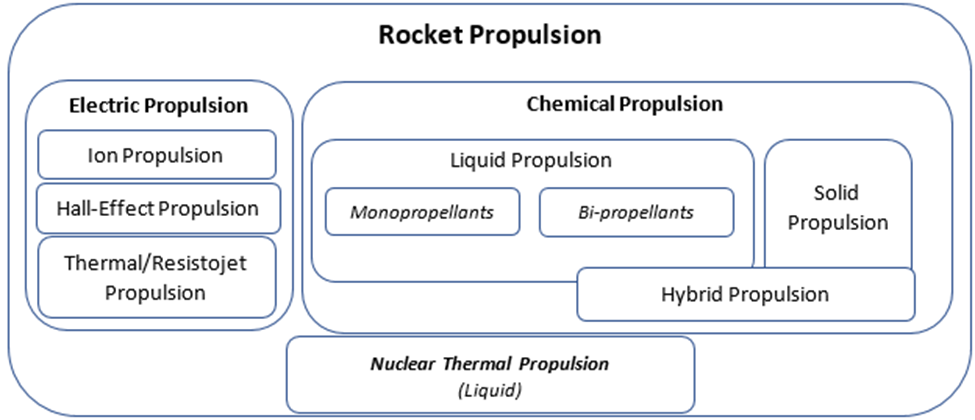

3. Revolutionary Propulsion Systems

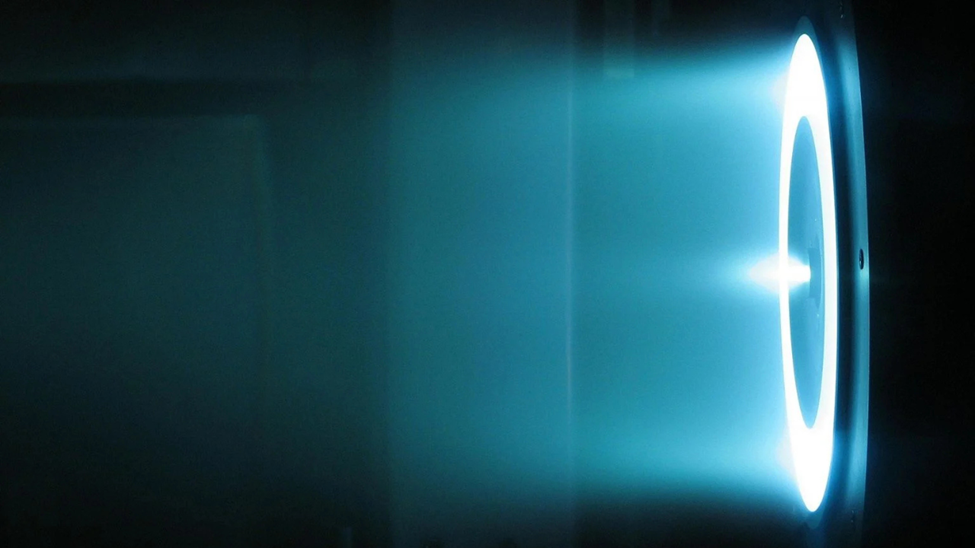

a. Electric Propulsion (Ion Thrusters, Hall Effect Thrusters)

While chemical rockets provide high thrust for launch, electric propulsion systems offer extremely high fuel efficiency (high specific impulse) for long-duration space travel. Ion thrusters, which accelerate charged particles, are ideal for orbital maneuvers and interplanetary journeys, requiring far less propellant mass. Future spaceships will increasingly utilize these for deep-space missions.

A solar electric propulsion Hall Effect thruster

b. Nuclear Propulsion (Nuclear Thermal and Nuclear Electric)

For truly rapid transit to Mars and beyond, nuclear propulsion is a focus of future tech. Nuclear thermal rockets use a nuclear reactor to heat propellant to extreme temperatures, expelling it for thrust. Nuclear electric propulsion uses a reactor to generate electricity for advanced electric thrusters. Both promise significantly faster transit times and greater payload capacity than current chemical systems, making ambitious human missions more feasible. This is a key area of US space investment.

c. Advanced Chemical Propulsion

Even traditional chemical rockets are being refined for greater efficiency and reusability. SpaceX's Raptor engine, for instance, uses a full-flow staged combustion cycle, which is highly efficient and designed for reusability, powering their Starship spacecraft.

4. Autonomy and Artificial Intelligence (AI)

a. Autonomous Navigation and Operations

Future spacecraft will possess enhanced autonomy, capable of making real-time decisions, navigating without constant human intervention, and adapting to unexpected conditions. This is essential for deep-space missions where communication delays with Earth are substantial. AI will be integrated into flight control, fault detection, and even scientific data analysis on board the spaceship.

b. Onboard Diagnostics and Self-Repair

AI-powered systems will monitor the health of the spacecraft, predict potential failures, and even initiate self-repair mechanisms using robotic arms or 3D printing. This dramatically increases mission reliability and reduces reliance on ground crews.

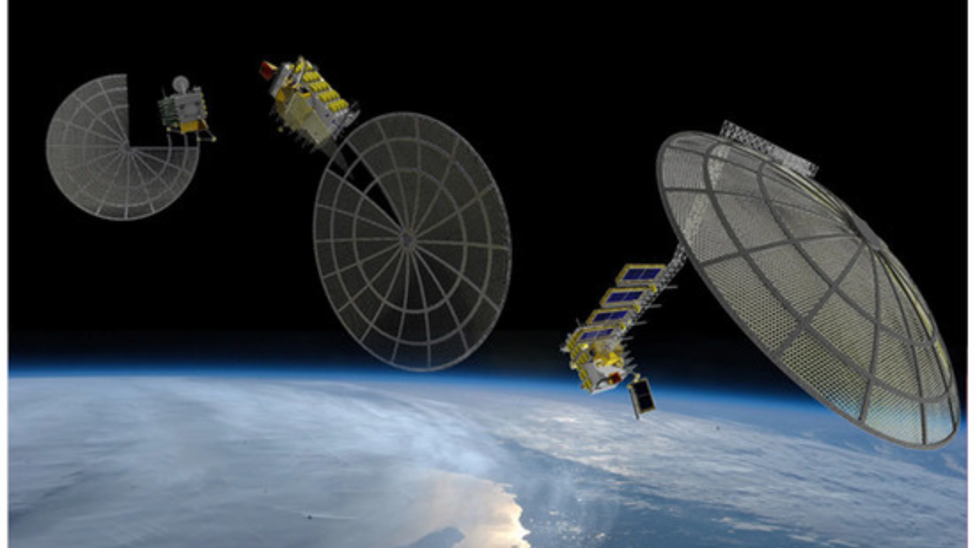

c. In-Orbit Servicing, Assembly, and Manufacturing (ISAM)

Instead of launching fully assembled spacecraft, future large structures (like space stations, large telescopes, or interplanetary vehicles) will be assembled in orbit by robotic systems. This bypasses the size constraints of launch vehicle fairings and allows for the construction of a truly massive spaceship.

In-Orbit Servicing, Assembly, and Manufacturing (ISAM)

d. On-orbit Manufacturing and Repair:

Future spacecraft will have the capability to manufacture spare parts or even new components in space using onboard 3D printers, and perform repairs, extending the lifespan of existing assets and enabling more complex missions. This is a vital part of future spacecraft operations.

How Spacecraft Are Built: The Evolving Process

The process of building a spaceship is undergoing a significant transformation. Traditionally, it involved highly specialized, custom-built designs with bespoke components. This led to high costs and long development cycles. The future emphasizes:

1. Vertical Integration (SpaceX model)

Companies like SpaceX have championed vertical integration, where they design, manufacture, and test a vast majority of their spacecraft components in-house. This gives them greater control over the supply chain, accelerates development, and reduces costs.

2. Rapid Iteration and Testing

The modern approach involves building and testing prototypes rapidly, learning from failures, and iterating designs quickly. This “fail fast, learn faster” philosophy, evident in SpaceX's Starship development, contrasts with the slower, more cautious approach of traditional aerospace.

3. Software-Defined Spacecraft

Increasingly, the capabilities of a spaceship are defined by its software. This allows for in-orbit updates, reconfigurable missions, and greater adaptability, making the physical spacecraft more flexible.

US and UK Space: Shaping the Future

Both the US and UK space sectors are making significant contributions to future spaceship technology.

The US, with NASA and a robust private sector including SpaceX, Blue Origin, and countless smaller companies, is leading in areas like heavy-lift launch (e.g., Starship, SLS), advanced propulsion (e.g., nuclear concepts), and deep-space human exploration. Investment in US space tech is heavily focused on Mars missions and lunar return.

The UK space industry, while smaller, is specializing in areas like small satellite manufacturing, advanced materials, and satellite servicing. The UK is developing its own spaceports and regulatory frameworks to support commercial launches and in-orbit operations, contributing to the global push for accessible spacecraft technology.

Buy Spacecraft Model / Explore Spacecraft Technology

For enthusiasts, exploring spacecraft technology can be done through various means:

- Books and Documentaries: Numerous resources explain the intricate details of spacecraft design and engineering.

- Museums and Visitor Centers: Space museums (like the Smithsonian National Air and Space Museum in the US or the National Space Centre in the UK) offer insights into historical and future spacecraft.

- Online Courses and Communities: Many universities offer online courses on space engineering, and online forums allow discussions on cutting-edge spacecraft technology.

- Spacecraft Models: For a tangible appreciation, you can buy spacecraft model kits or pre-built models, ranging from detailed replicas of existing vehicles to conceptual future designs.

The future of spacecraft is one of incredible potential, driven by innovation that will transform our ability to explore, live, and work beyond Earth. These advancements in spacecraft are not just about reaching new destinations; they are about opening up a new era of human enterprise in space.