The dawn of a new era in space exploration is upon us, marked by an increasingly ambitious vision: building spacecraft in the very environment they are destined to traverse – zero gravity. This revolutionary approach, moving manufacturing from Earth's gravitational pull to the vacuum of space, promises to unlock unprecedented capabilities and reshape the future of space travel. The concept of a zero gravity spacecraft constructed in orbit is no longer science fiction but a rapidly developing reality.

Zero Gravity Spacecraft: A Paradigm Shift in Construction

The idea of a zero gravity spacecraft being built off-world is driven by several compelling advantages. On Earth, the size and shape of spacecraft are constrained by the need to withstand the intense forces of launch and the limitations of payload fairings. Components must be robust enough to endure vibrations and G-forces, often leading to over-engineered structures and significant weight penalties. However, in the microgravity environment of space, these constraints vanish.

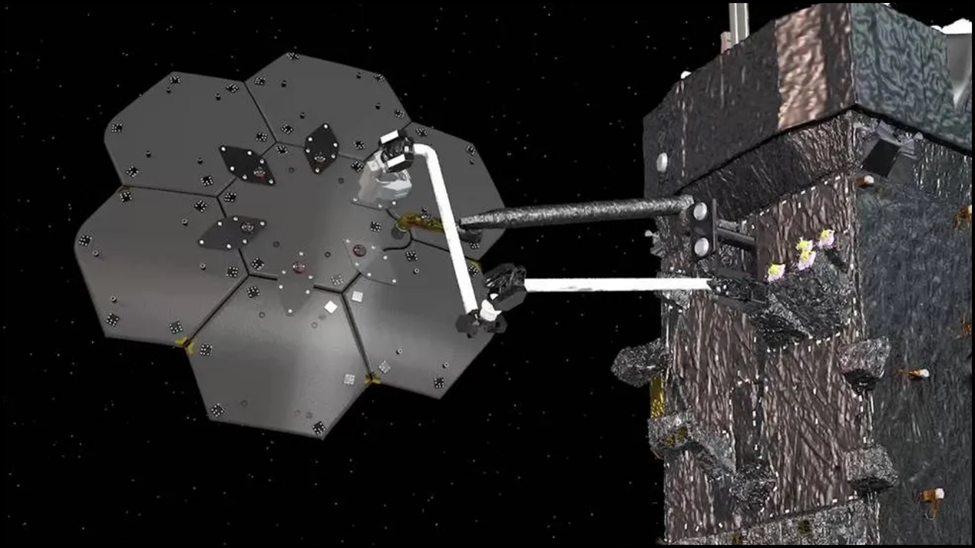

A zero-gravity spacecraft can be assembled from larger, more delicate components that would never survive a terrestrial launch. Think of immense, gossamer-thin solar arrays spanning kilometers, or colossal optical telescopes with mirrors far larger than anything currently deployed. These structures, too fragile for Earth's launchpads, become feasible when built piece by piece in orbit. The ability to create truly massive and high-performance zero gravity spacecraft is a game-changer for deep-space missions, asteroid mining, and even orbital habitats.

Building Spacecraft in Zero Gravity: The Orbital Advantage

Building spacecraft in zero gravity fundamentally alters the design process. Materials can be optimized for the space environment itself, rather than for launch survival. This means lighter, more efficient, and potentially more specialized materials can be utilized. Furthermore, processes like additive manufacturing (3D printing) thrive in zero gravity. Without convection or sedimentation, molten metals and other materials can cool more uniformly, leading to purer alloys and stronger structures. This leads to superior quality control for every component of a zero-gravity spacecraft.

The vacuum of space also offers a pristine environment, free from atmospheric contamination, which is ideal for manufacturing sensitive components like advanced electronics or optical lenses. The prospect of in-space manufacturing facilities producing complex parts for a zero gravity spacecraft on demand, without the need for Earth-based resupply missions, represents a significant leap forward in logistical independence for space operations.

Buy Zero Gravity Technology: Investing in the Off-World Economy

The nascent market for zero gravity technology is rapidly expanding, attracting significant investment from both government agencies and private enterprises. Companies are developing specialized robotics, advanced 3D printers designed for space, and automated assembly systems specifically for building a zero gravity spacecraft. These technologies are critical enablers for orbital construction.

As the demand for in-space manufacturing grows, we can expect to see a burgeoning market for services and products related to zero-gravity spacecraft construction. This includes everything from orbital assembly platforms and robotic construction crews to advanced materials tailored for the space environment. Investing in these pioneering companies is investing in the infrastructure of tomorrow's space economy, where the assembly of a zero gravity spacecraft is a routine operation.

How Zero Gravity Affects Spacecraft: Design and Operations

While seemingly advantageous, zero gravity also presents unique challenges for the design and operation of a zero-gravity spacecraft. The absence of a “down” makes orientation and material handling complex. Astronauts and robots must contend with objects floating freely, requiring specialized tools and training. Fluid dynamics behave unpredictably in microgravity, impacting fuel transfer, thermal management, and life support systems.

Furthermore, long-term exposure to radiation and micrometeoroid impacts remains a constant threat, necessitating robust shielding and repair capabilities for any zero-gravity spacecraft. Designers must also consider the psychological and physiological effects on human crews if they are involved in the construction or operation of these large orbital structures. Solutions often involve sophisticated robotic systems, advanced sensor technology, and innovative propulsion methods for precise maneuvering of components during assembly of a zero gravity spacecraft.

Follow Space Tech News: Staying Ahead of the Curve

To keep abreast of these rapid developments, it is essential to follow space tech news. Major breakthroughs in orbital manufacturing, new materials science discoveries for zero-gravity spacecraft, and mission announcements are frequent. Publications like SpaceNews, Ars Technica's space section, and specific company newsrooms provide invaluable insights into the progress being made.

The evolving capabilities of 3D printing in space, advancements in robotic assembly, and the increasingly ambitious plans for in-orbit construction are regularly reported. Keeping an eye on these developments offers a window into the tangible progress towards realizing the vision of advanced zero gravity spacecraft.

NASA, SpaceX, US and UK Space Tech: Leading the Charge

Leading space agencies and private companies are at the forefront of this revolution. NASA has long been researching in-space manufacturing and assembly, conducting experiments on the International Space Station (ISS) to understand how materials behave and how robots can perform complex tasks in microgravity. Their In-Space Production Applications (InSPA) portfolio is actively funding commercial endeavors to demonstrate the viability of manufacturing products, including components for a zero gravity spacecraft, in orbit.

SpaceX, with its ambitious Starship program, envisions a future where large structures, potentially including elements of a zero gravity spacecraft, are assembled in Earth orbit before proceeding to the Moon or Mars. Their focus on reusability and high launch cadence makes orbital assembly a more economically viable proposition.

The US space tech sector, encompassing both government and private entities, is a global leader in advancing these capabilities. Investments in robotic manipulation, autonomous systems, and advanced materials are paving the way for larger and more capable zero gravity spacecraft.

Across the Atlantic, UK space tech is also making significant strides. Companies like Space Forge are focused on in-space manufacturing, leveraging the unique conditions of microgravity to produce advanced materials for terrestrial applications, with a clear roadmap towards larger orbital construction projects. Their ForgeStar®-1 mission, for instance, is testing in-space manufacturing and reusable re-entry, vital steps towards building larger zero gravity spacecraft in the future. These collaborations and national efforts are crucial for accelerating the transition to off-world construction.

Space Travel: Redefining the Journey

Ultimately, the future of zero gravity spacecraft is intrinsically linked to the future of space travel itself. Larger, more robust, and more efficiently designed spacecraft built in orbit will enable longer-duration missions to distant destinations. Imagine interstellar probes assembled with colossal antennas, or self-sustaining habitats for Mars colonists, all constructed piece by piece in the weightlessness of space.

The ability to create highly specialized zero gravity spacecraft opens up possibilities for revolutionary scientific instruments, advanced resource extraction vehicles, and even orbital tourism platforms that offer unparalleled experiences. The journey through the cosmos will no longer be limited by the constraints of terrestrial launch, but by the imagination and ingenuity of engineers and scientists operating in the ultimate construction zone: space. The zero gravity spacecraft will be the backbone of humanity's expansion beyond Earth.