When we talk about plastic recycling, we often imagine everyday items like bottles, packaging, and containers being melted down and reformed. But high heat resistant plastic—the kind used in aerospace components, automotive parts, medical devices, and industrial machinery—has always been a tough challenge for recyclers. These materials are designed to withstand extreme temperatures without deforming, which makes them invaluable in engineering but notoriously difficult to recycle.

Thanks to innovative plastic recycling technologies, this is starting to change. Researchers and manufacturers are now exploring new ways to recover, reuse, and repurpose recyclable high heat resistant plastics, paving the way for a more sustainable plastics industry.

Why High Heat Resistant Plastic Matters

High heat resistant plastics—like polyether ether ketone (PEEK), polyimide, and certain high-performance polyamides—can tolerate temperatures well above 250°C without losing structural integrity. Their durability makes them ideal for applications where traditional plastics would melt, warp, or degrade.

However, this same durability means they require specialized recycling techniques. Traditional recycling processes, which rely on melting plastics at moderate temperatures, are ineffective. Without innovation, these materials often end up in landfills or incinerators, contributing to environmental challenges.

The Recycling Challenge: Technical Barriers, Cost Factors, and Industry Shifts

The main hurdle in recycling high heat resistant plastic lies in its extraordinary temperature tolerance.

1. Technical Barriers

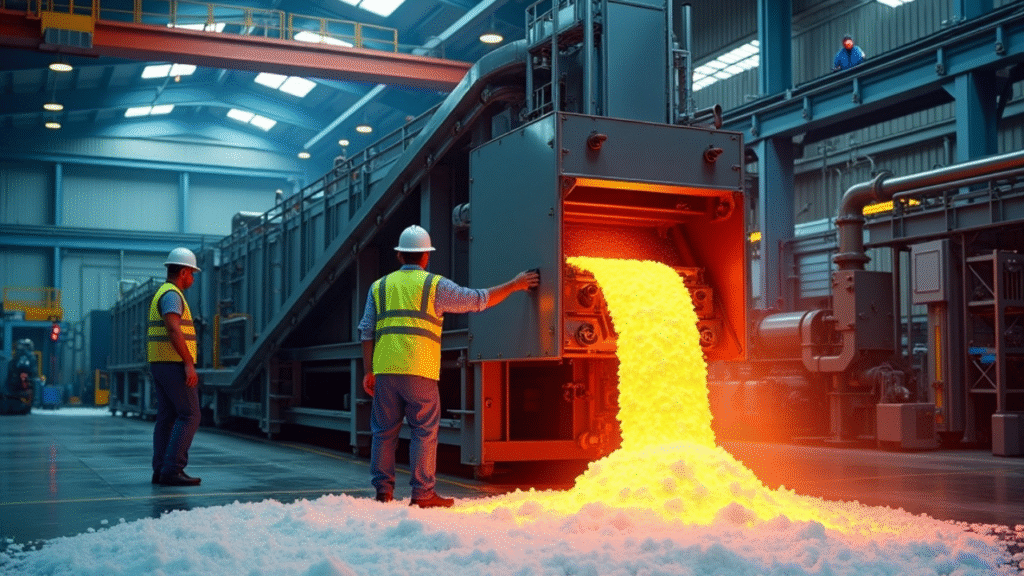

Unlike conventional plastics that melt at relatively low temperatures, these materials require recycling facilities to operate at extremely high heat levels or use advanced chemical processes to break the polymers down into their base components. Such specialized methods demand cutting-edge machinery and highly skilled operators.

2. Cost and Infrastructure Limitations

These advanced requirements come at a cost—literally. The equipment and energy needed to process eco-friendly heat resistant materials are significantly more expensive than those used for standard plastic recycling. This not only raises production costs but also limits the number of facilities worldwide that can handle the task, creating a bottleneck in the recycling chain.

3. Industry Shifts and Growing Momentum

For decades, heat resistant plastic recycling was not considered economically viable on a large scale. However, the narrative is changing. With increasing demand for sustainable plastics, stricter waste management regulations, and a growing awareness of environmental impact, industries are now investing in advanced plastic recycling methods. This shift signals a promising future where even the most challenging materials can be part of a truly circular economy.

Breakthrough Recycling Technologies

Several innovations are now making high-temperature plastic reuse possible:

1. Chemical Recycling

Instead of melting plastics, chemical recycling breaks down polymers into their basic building blocks (monomers), which can be purified and reused to create new materials with the same high-performance properties.

2. Supercritical Fluid Technology

Using supercritical water or carbon dioxide, plastics can be decomposed at relatively lower temperatures than traditional thermal methods, making it energy-efficient and reducing degradation of the recovered materials.

3. High-Temperature Mechanical Recycling

Specialized extrusion systems capable of operating at extremely high temperatures allow industrial heat resistant plastics to be reprocessed into pellets for manufacturing new products.

4. Blending and Composite Manufacturing

Some recyclers mix recovered recyclable high heat resistant plastic with other polymers or fillers to produce durable composite materials for construction, automotive, and aerospace applications.

Applications for Recycled High Heat Resistant Plastics

The recovered materials are finding new life in:

- Automotive Components – under-the-hood parts, engine covers, and brake systems.

- Aerospace Parts – lightweight, heat-resistant interior and exterior components.

- Medical Devices – sterilizable surgical instruments and housings for medical equipment.

- Industrial Equipment – high-temperature seals, valves, and machine parts.

By reusing these materials, manufacturers not only cut costs but also reduce reliance on virgin resources, contributing to a circular economy in plastics.

Environmental Impact and Future Outlook

The shift towards recycling high heat resistant plastic has far-reaching benefits. It reduces landfill waste, lowers greenhouse gas emissions from incineration, and decreases the need for fossil fuel-based virgin polymers.

1. Positive Environmental Impact

By diverting these durable plastics from landfills, we significantly cut down on long-term pollution and conserve valuable natural resources. Recycling also minimizes the carbon footprint associated with producing virgin materials.

2. Industry Growth and Opportunities

As technology advances and sustainable plastics gain market traction, we can expect more industries—from automotive to aerospace—to integrate recycled high-performance materials into their products. This opens new markets, fosters innovation, and supports a growing green economy.

3. Future Outlook

Government incentives, stricter waste regulations, and consumer demand for eco-friendly solutions will only accelerate this trend, making high heat resistant plastic recycling a critical part of the circular economy.

Final Thoughts

High heat resistant plastic recycling is no longer a distant dream—it’s an emerging reality. While challenges remain in scaling these technologies, the progress being made is promising. With continued research and collaboration between manufacturers, recyclers, and policymakers, these materials could become a cornerstone of the next generation of innovative plastic recycling technologies.

In the race toward a greener future, no material should be left behind—not even the most unmeltable plastics.